-

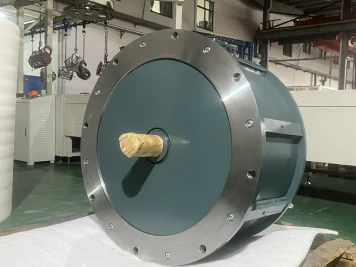

Permanent Magnet Motor

-

Wind Turbines

-

Permanent Magnet Drive

-

Service Support

-

About Hiest

-

News

It has become a trend that the stirring motor of the reactor in the rare earth industry replaces the original asynchronous motor acceleration and deceleration mode with a direct drive motor.

For the low-speed and high-torque working conditions of the industry, the asynchronous motor with reducer transmission drive mode increases the output torque through the reducer to meet the load demand, but it is precisely because of the existence of the reducer, will lead to transmission efficiency loss, oil leakage, maintenance and other failure points. When the direct drive motor drives the load, it does not need to go through the transmission device (such as transmission belt, etc.), the load is directly connected to the motor, and there is no reducer in the middle, which can not only fully meet the needs of high output torque, but also simplify the mechanical structure, reduce maintenance costs, improve the stability and efficiency of the reactor equipment operation, and greatly improve the energy saving rate.