-

Permanent Magnet Motor

-

Wind Turbines

-

Permanent Magnet Drive

-

Service Support

-

About Hiest

-

News

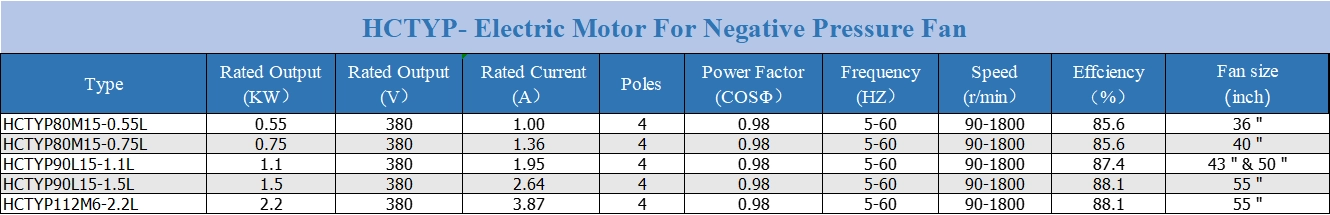

Product Description

Hiest devotes itself in R&D,design, production and application of motors such as“Asynchronous Starting Permanent Magnet Synchronous Motor”,“Frequency Controlled Permanent Magnet Synchronous Motor”and“ Drive-control Integrated Permanent Magnet Synchronous Motor”which represent the further development direction of motor industry.

Featured by simple structure,small size,high efficiency,wide amplitude modulation and low noise,the series products of Hiest are ideal optional products for ventilation and cooling motors in animal husbandry.With efficiency index of IE4 or above national Class 2 energy efficiency and featured by high starting torque,simple structure,small size and lose noise,can replace the traditional asynchronous motors directly.

Integration of motor and drive ensures compact appearance and avoids excessive wiring.Integrated design can bring easy installation and use of terminal user.Drive is controlled via vector algorithm,to connect IoT and control multiple machines, have fast and comprehensive management.

Our fan motors are widely applied in the large livestock farms in the USA,Canada and Europe.

The permanent magnet motor consists of stator, rotor, bearing device, end cover, junction box, fan/fan cover, in which, the stator is a fixed part of motor and consists of one stator core, base and 3-phase field winding. The rotor, as the revolving part of motor, is mounted with permanent magnet poles. Hiest provides customers with a series of standard and customized permanent magnet synchronous motors which have the following characteristics compared with the traditional asynchronous motors: